Product List

- Ball Valves

- Flanged Floating Ball Valve

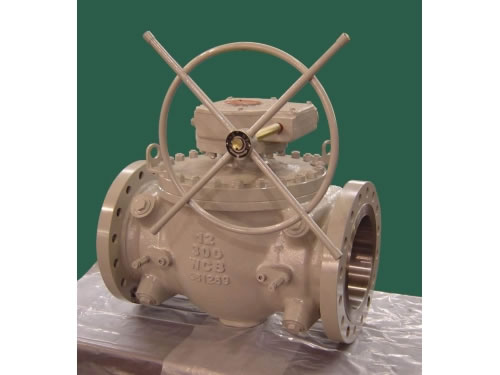

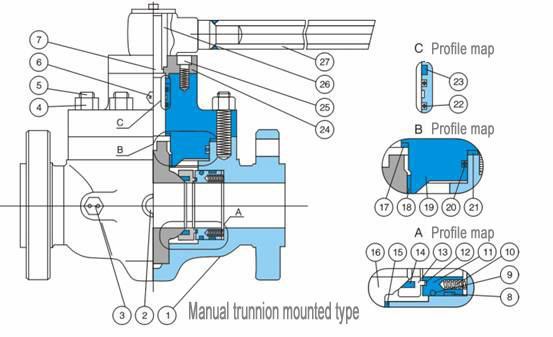

- Trunnion Mounted Ball Valves

- API 2PC Flanged Trunnion Mounted Ball Valve

- API 3PC Flanged Trunnion Mounted Ball Valve

- API 6D Trunnion Mounted Ball Valve

- DIN 3PC Flange Forged Steel Trunnion Mounted Ball Valve

- DIN Top Entry Ball Valve

- DBB Flanged Ball valve

- DBB Flanged & Welded Ball Valve

- DBB Threaded Ball Valve

- Threaded Ball Valves

- Welded End Ball Valves

- Gate Valves

- Flanged Gate Valves

- Welded Gate Valves

- Threaded Gate Valves

- Globe Valves

- Flanged Globe Valves

- Weld End Globe Valves

- Threaded Globe Valves

- Check Valves

- Flanged Check Valves

- Welded Ends Check Valves

- Threaded Check Valves

- Y Type Strainers

- Flanged Y Type Strainers

- Threaded Y Type Strainers

- Forged Steel Valves

- Flanged Forged Steel Valves

- Threaded Forged Steel Valves

- Welded Ends Forged Steel Valves