- Ball Valves

- Flanged Floating Ball Valve

- Trunnion Mounted Ball Valves

- API 2PC Flanged Trunnion Mounted Ball Valve

- API 3PC Flanged Trunnion Mounted Ball Valve

- API 6D Trunnion Mounted Ball Valve

- DIN 3PC Flange Forged Steel Trunnion Mounted Ball Valve

- DIN Top Entry Ball Valve

- DBB Flanged Ball valve

- DBB Flanged & Welded Ball Valve

- DBB Threaded Ball Valve

- Threaded Ball Valves

- Welded End Ball Valves

- Gate Valves

- Flanged Gate Valves

- Welded Gate Valves

- Threaded Gate Valves

- Globe Valves

- Flanged Globe Valves

- Weld End Globe Valves

- Threaded Globe Valves

- Check Valves

- Flanged Check Valves

- Welded Ends Check Valves

- Threaded Check Valves

- Y Type Strainers

- Flanged Y Type Strainers

- Threaded Y Type Strainers

- Forged Steel Valves

- Flanged Forged Steel Valves

- Threaded Forged Steel Valves

- Welded Ends Forged Steel Valves

DIN 3PC Flange Forged Steel Trunnion Mounted Ball Valve

Description

DIN 3PC forged steel trunnion mounted ball valve has additional mechanical anchoring of the ball at the top and the bottom, suitable for larger and higher pressure valves. This forged steel ball valve is often combined with floating valve seat, which will move to press the seal ring on the ball under the pressure of media, guaranteeing the sealing performance.

Application

Trunnion mounted ball valve can be widely used in such pipelines as tap water, sewage, construction, petroleum, chemical, food, medicine, textile, electric power, shipbuilding, metallurgy, energy systems, etc.

Advantages

1. This forged steel ball valve features excellent sealing performance, low friction between sealing surfaces and long service life.

2. Its surface is finished second time, thus this 3PC ball valve is smooth and bright. The bonnet is processed by numerical control machine.

3. Our trunnion mounted ball valves are guaranteed within 18 months and enjoy lifelong technical service.

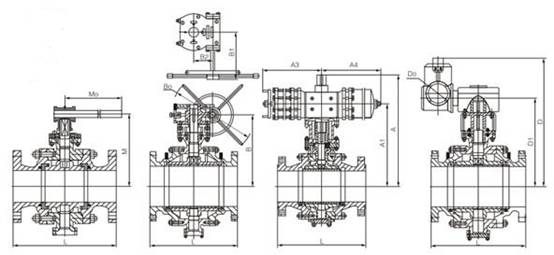

Structure of DIN 3PC Forged Steel Trunnion Mounted Ball Valve

| Handle Operation | Worm Gear Operation | Pneumatic Operation | Electric Operation |

| A(G)TB1RF1 | A(G)3TB1RF1 | A(G)6TB1RF1 | A(G)9TB1RF1 |

| A(G)TB1BW1 | A(G)6TB1BW1 | A(G)6TB1BW1 | A(G)9TB1BW1 |

Components of DIN 3PC Forged Steel Trunnion Mounted Ball Valve

| No. | Parts | Materials | No. | Parts | Materials | |||||||

| Carbon Steel | Stainless Steel | Low Temperature Steel | Carbon Steel | Stainless Steel | Low Temperature Steel | |||||||

| 1 | Valve Body | ASTM A105 | A182 F304 | A350 LF2 | 19 | Grease Injection Valve | ASTM A105 | A182 F304 | A350 LF2 | |||

| 2 | Gasket | Flexible Graphite + SS | 20 | Upper Bushing | PTFE + CS | PTFE+SS | PTFE+SS | |||||

| 3 | Bleeder Valve | ASTM A105 | A182 F304 | A350 LF2 | 21 | Valve Stem | A182 F6a | A182 F304 | A182 F304 | |||

| 4 | Bottom Cap | ASTM A105 | A182 F304 | A350 LF2 | 22 | Flat Bushing | PTFE + CS | PTFE+SS | PTFE+SS | |||

| 5 | Bolt | A193 B7 | A193 B8 | A320 L7 | 23 | Yoke | A216 WCB | |||||

| 6 | Gasket | Flexible Graphite + SS | 24 | Adapter Sleeve | ANSI 1025 | |||||||

| 7 | O-ring | Fluororubber | 25 | Bolt | A193 B7 | |||||||

| 8 | Lower Bushing | PTFE + CS | PTFE + SS | PTFE + SS | 26 | O-ring | Fluororubber | |||||

| 9 | Ball | ASTM A105+ENP |

A182 F304 | A182 F304 | 27 | O-ring | Fluororubber | |||||

| 10 | Flange Gasket | Flexible Graphite + SS | 28 | Gasket | Flexible Graphite + SS | |||||||

| 11 | O-ring | Fluororubber | 29 | Upper Valve Seat | ASTM A105 | A182 F304 | A350 LF2 | |||||

| 12 | Firewall | Flexible Graphite | 30 | Locating Pin | A182 F6a | |||||||

| 13 | Seal Ring | PTFE, NYLON, PEEK, MOLON, PCTFE | 31 | Bolt | A193 B7 | |||||||

| 14 | Valve Seat | ASTM A105 + ENP |

A182 F304 | A182 F304 | 32 | Worm Screw and Worm Gear | / | |||||

| 15 | Spring | Inconel600 | 33 | Grease Injection Valve | ASTM A105 | A182 F304 | A350 LF2 | |||||

| 16 | Bolt | A193 B7 | A193 B8 | A320 L7 | PS: 1) Sealing materials should be chosen according to the temperature and pressure of media. 2. Besides those materials listed above, we can use materials that customers require. |

|||||||

| 17 | Nut | A194 2H | A194 8 | A194 7 | ||||||||

| 18 | Bonnet | ASTM A105 | A182 F304 | A350 LF2 | ||||||||

Technical Parameters of DIN 3PC Forged Steel Trunnion Mounted Ball Valve

In column L, RF indicates the length of the convex flange structure, WE indicates welding structure length, and RJ indicates length of connection structure.

- DIN Top Entry Ball ValveKayson developed an advanced design of DIN top entry ball valves, in a complete wide range of diameters and pressure classes. This top entry trunnion mounted ball valve is the perfect choice when on line maintenance is required. The valve allows free access to the body cavity without dismantling the valve from the line. Users can replace the parts they want to change...