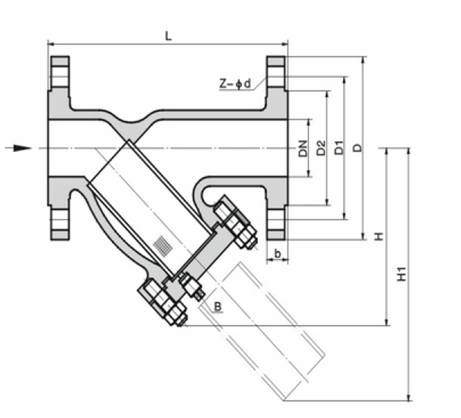

API Stainless Steel Flanged Y Strainer

Description

API stainless steel flanged Y strainer is an essential device for medium transmission pipeline system. It is installed on pipeline and helps to remove bigger solid particles in fluid, such as iron rust and sand grain in the sewage. This stainless steel Y strainer can protect pipeline accessories (compressor, pump, display instrument, etc.) from wearing and blocking in order to keep the medium transmission pipeline system work smoothly. This API flanged Y strainer is used in various pipeline systems, such as tap water, sewage, construction, petroleum, chemical, food, medicine, textile, electric power, shipbuilding, metallurgy, energy, etc.

Features

1. The sealing surface on our API flanged Y strainer is of high corrosion, rub, erosion, and oxidation resistance.

2. Filter mesh is made of thickened stainless steel plate, which ensures its long serve life.

3. This Y strainer features high filtration precision and strong fouling resistance.

4. Maintenance of stainless steel Y strainer is very easy and convenient. You just need to dismount the filter cylinder.

5. Precision casting technique is adopted for manufacturing strainer.

Main Components and Ingredients of API Flanged Y Strainer

| Name of Parts |

Material |

| Valve Body |

Stainless Steel |

| Strainer Cover |

Stainless Steel |

| Strainer Mesh |

Stainless Steel |

| Sealing Element |

Flexible Graphite and Telfon |

Classification by Sealing Surface

Sealing surface is the most important working face of API flanged Y strainer. According to ingredients, these stainless steel Y strainers are classified into two types:

1. Soft Sealing Material

(1)Rubber (like Nitrile rubber, fluoro rubber, etc.)

(2)Plastic (Teflon, nylon, etc.)

2. Hard Sealing Material

(1)Copper Alloy (for low pressure resistant strainer)

(2)Chromium Stainless Steel (for common middle or high pressure resistant strainer)

(3)Stellite Alloy (for high temperature and pressure resistant and highly anti-corrosive strainer)

(4)Nickel Based Alloy (for anti-corrosive strainer)

Attentions

1. Nominal Pressure: Pressure rating of API flanged Y strainer is determined by the maximum pressure of filtration pipeline.

2. Entrance and Exit Diameter: Generally, entrance and exit diameter of strainer should not be smaller than the entrance diameter of the supporting pump, and agree with the diameter of entrance pipeline.

3. Size of the Mesh: When choosing mesh size, you should consider the diameter of the impurity.

4. Material of Filter: Material of stainless steel Y strainer is similar with pipeline it connects. You can choose casting iron, carbon steel, low alloy steel and stainless steel Y filters considering your different serving conditions.

Kayson products, such as ball valves, gate valves, globe valves, check valves, forged steel valves and stainless steel Y strainers, have reached the standard of US API, Germany DIN, Russia GOST, Japan JIS, ISO9001 and CE. Our API flanged Y strainers are broadly applied in various pipeline systems, such as tap water, sewage, construction, petroleum, chemical, food, medicine, textile, electric power, shipbuilding, metallurgy, energy, etc. Our products occupy a large market at Brazil, Argentina, Mexico, Canada, Russia, Kazakhstan, Indonesia, South Korea, Japan and other foreign countries.

Related Product

- DIN Cast Steel Flanged Y StrainerDIN cast steel flanged Y strainer is an important device for medium transmission pipeline system. It is installed on pipeline and helps to remove big solid particles in fluid, such as iron rust and sand grain in the sewage. This DIN pipeline strainer can protect pipeline accessories (compressor, pump, display instrument, and other devices) from wearing and blocking...